We have enough manpower to give you timely delivery of the goods.

Above all we have a NOC from the GPCB of Gujarat.

We assure you the best quality at reasonable rates.

Though our establishment is a manual type plating plant, but, we have semi automated the plant where ever necessary.

To achieve the uniform results, we have installed the following,

– DUST PROOF ENVIRONMENT.

– TIMERS: for all the processes

– TEMPERATURE CONTROLLERS.

– LABORATORY: To check the strength of chemicals we use

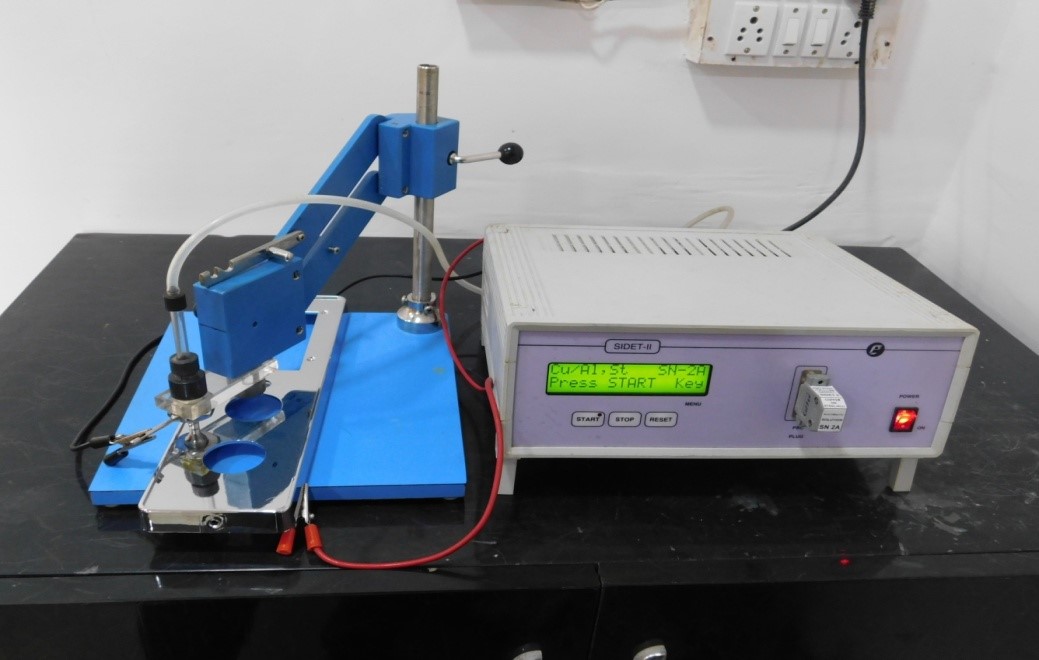

– HULL CELL facility.

– VISUAL AIDS: To check the material visually.

– CARTRIDGE FILTERS

– PH METERS, TDS METER, HYDRO METER etc.

– WE use entire chemistry of ATOTECH Germany.

THICKNESS TESTING MACHINE

The Laboratory team is the unit responsible for ensuring that final outcomes are reliable, can meet technical requirements, and that adopted methodology is adhered to.

– The quality team members work closely with the process.

– The laboratory team works hand in hand with the QC (Quality Control) department to ensure least plating rejection and consistent outcome.

– The Laboratory team is also equipped with THICKNESS TESTING machine.

– This method is adopted for consistent plating results.

– As electroplating is a multi-layer process, we ensure each layer is as per standards set by us and also give by customer.

– We adopt following standards for consistent plating results:

1 |

Bright Copper |

Min. 12 µm |

2 |

Bright Nickel |

Min. 5 µm |

3 |

Bright Chrome |

Min. 0.35 µm |

4 |

CASS test |

Min. 72 hrs. |